- Ball Valves

BHOLA ENGINEERS PRIVATE LIMITED is a leading manufacturer of high-quality valves. We offer a comprehensive range of ball valves that are designed to meet even the most demanding application requirements.

Our Ball Valves are available in a wide range of designs, materials, sizes, and pressure classes. They fully conform to ANSI, API, and NACE specifications. All our ball valves are designed in accordance with ASME B16.34 and, wherever applicable, with API 6D or BS EN ISO 17292.

The BEPL family of ball valves is specifically engineered to provide reliable shut-off for fluids and gases, even under extreme service conditions.

Features & Benefits of Ball Valves

- ]All BEPL Trunnion ball valves are equipped with two body gaskets. The first body gasket is in soft material and the second in Graphite .

- ]In order to prevent static electricity which may light the fluid , static-conduction spring is set between the stem / trunnion and the ball.

- ]The stem is designed with integral T-Type shoulder to provide blow-out proof effectively. The design assures that the stem can not be blown out of the valve in the case of the packing being removed while the valve is under pressure.

- ]Stem and stuffing box finish machining is a key point of control. The stem is made by cold rolling and stem surface finish is controlled by Ra=0.4, which can reduce friction for stem moving and ensure the seal. The stuffing box surface is controlled within Ra=1.6 for better sealing performance.

- ]The solid ball used by BEPL provides straight through flow and real full-port performance characteristics. Hollow ball or cored cavity ball are not used for BEPL products.

- Stem / Flange mechanical stops ensure control and precise alignment over ball rotation.

- Valve design combined with the selection of advanced material are such that long periods of inactivity should not affect the operations of efficiency.

- Seat designs , stem-bearing system and stem seal arrangement ensure consistent minimal torque values.

- Valve design allows for high flow capacity in liquid or gas services regardless of whether the media is clean or dirty. Full port valves allow for pigging and ensure maximum flow capacity.

- Simple user friendly design allows for quick and easy part replacement requiring minimal “Down Time”ISO 5211 Flange is mounted in the valve as standard design.

- For 2” full port and larger valves, each of them have an emergency stem sealant injection feature.

- Stem / Flange mechanical stops ensure control and precise alignment over ball rotation.

- Every valve is subjected on routine base to different non-destructive testing, like the Liquid Penetrant test on butt weld ends, on all hard faced and cladding areas.

- Non-destructive test are also carried out on the critical areas as defined by ANSI B 16.34

- Personnel performing NDT are trained and Qualified to EN 473 /ASNT-SNT-TC-1A. Every valve is subject to a pressure test in accordance with the standard API 598 or BS 6755 Part 1.

- The rated pressure for the applicable pressure class is in accordance with ANSI B.16.34 / EN 12516-1-2.

Types Of Ball Valves

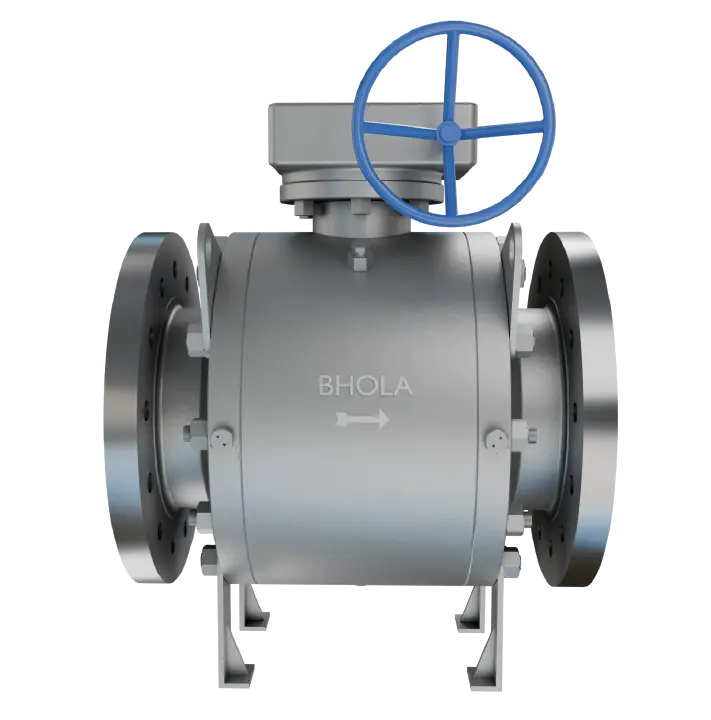

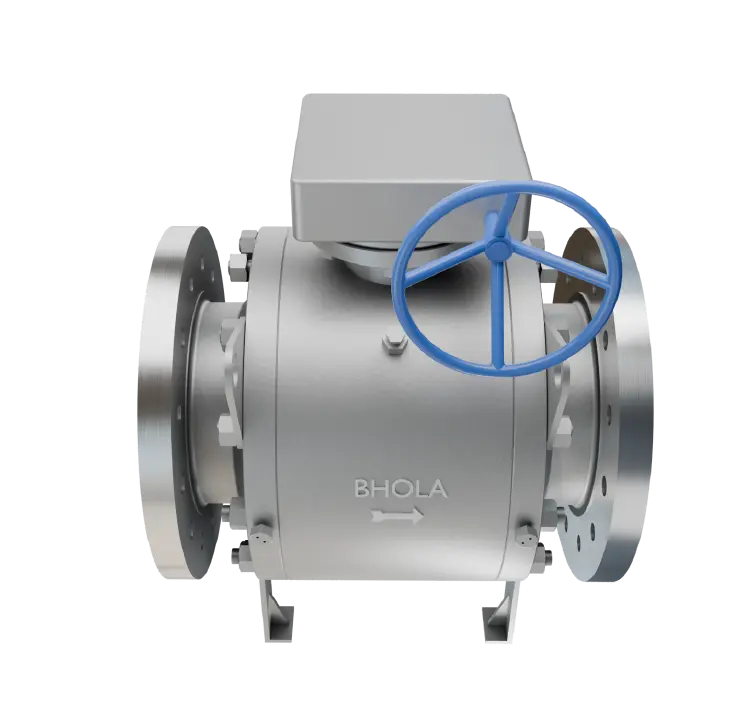

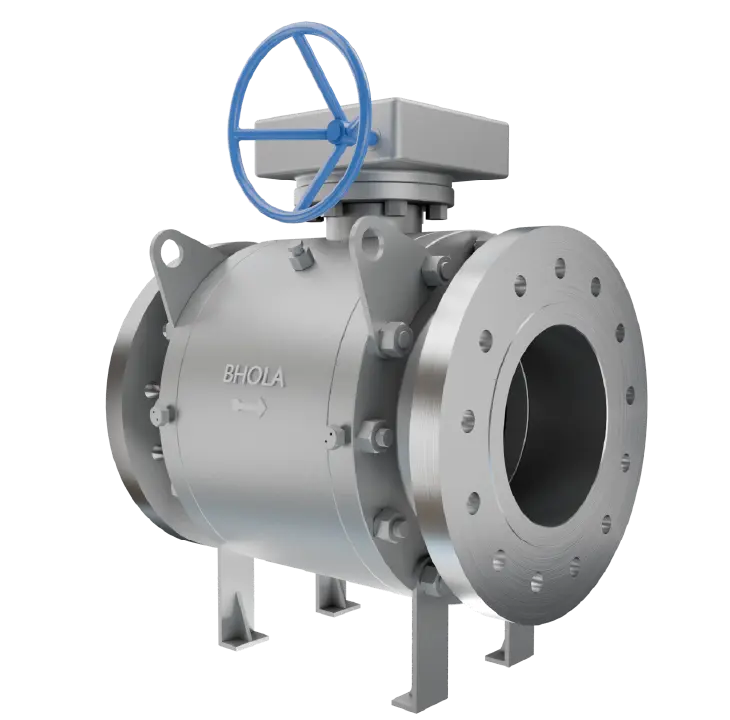

- ]TRUNNION MOUNTED BALL VALVE

- ]FLOATING BALL VALVES

- ]TOP ENTRY TYPE BALL VALVE

- ]CRYOGENIC VALVES