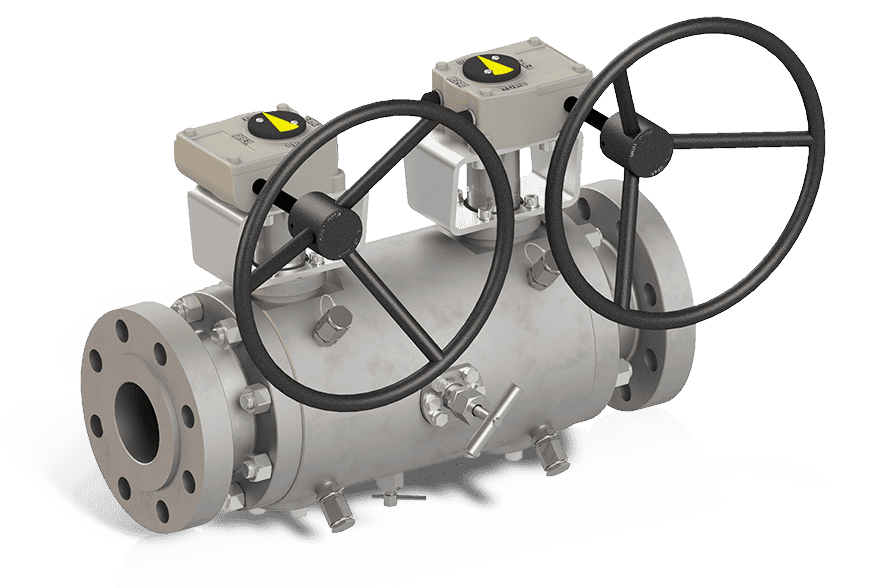

- Double Block & Bleed Valve

The growing activity in the offshore sector of the energy industry has introduced new considerations in the design of piping systems. In these modern locations, space is always limited, necessitating more compact designs for piping systems and their associated components. Additionally, there are crucial structural constraints, such as the need to keep the structure as lightweight as possible. Consequently, there are clear advantages in making components smaller and lighter. Moreover, the cost of construction site labor is exorbitant, making any reduction in installation manpower highly advantageous.

Given these circumstances, valve components have been modified to incorporate space, weight, and labor cost savings whenever feasible, while still maintaining their original functionality. The most significant savings can be observed in the reduction of leaks to the atmosphere, as potential leak points are minimized compared to conventional designs.

Furthermore, the philosophy of process isolation has become more intricate due to safety concerns. The requirement for double block and bleed isolation has become increasingly prevalent. This approach necessitates the use of two in-line isolation valves and a bleed valve, which is employed to drain or vent trapped fluid between the two closure elements.

In conclusion, the surge in offshore energy industry activity has necessitated a re-evaluation of piping system design. The need for compactness, lightweight structures, and reduced labor costs has driven the modification of valve components. Additionally, the focus on safety has led to the adoption of double block and bleed isolation as a common practice. These developments not only enhance efficiency but also ensure the integrity of the systems.

Features & Benefits of Double Block & Bleed Valves

- ]IMPROVED SAFETY IN OPERATIONS , SPACE , WEIGHT AND COST SAVINGS

- ]REDUCED INSTALLATION AND MAINTENANCE REQUIREMENTS AND COSTS

- ]REDUCED LEAKAGE POINTS , COMPACT DESIGN

- ]UNINTERRUPTED FLOW FOR NEGLIGIBLE PRESSURE DROP

- ]REDUCED STRESSES FROM LOADING AND VIBRATION

- ]DESIGNED AND ENGINEERED ON A CASE-BY- CASE BASIS