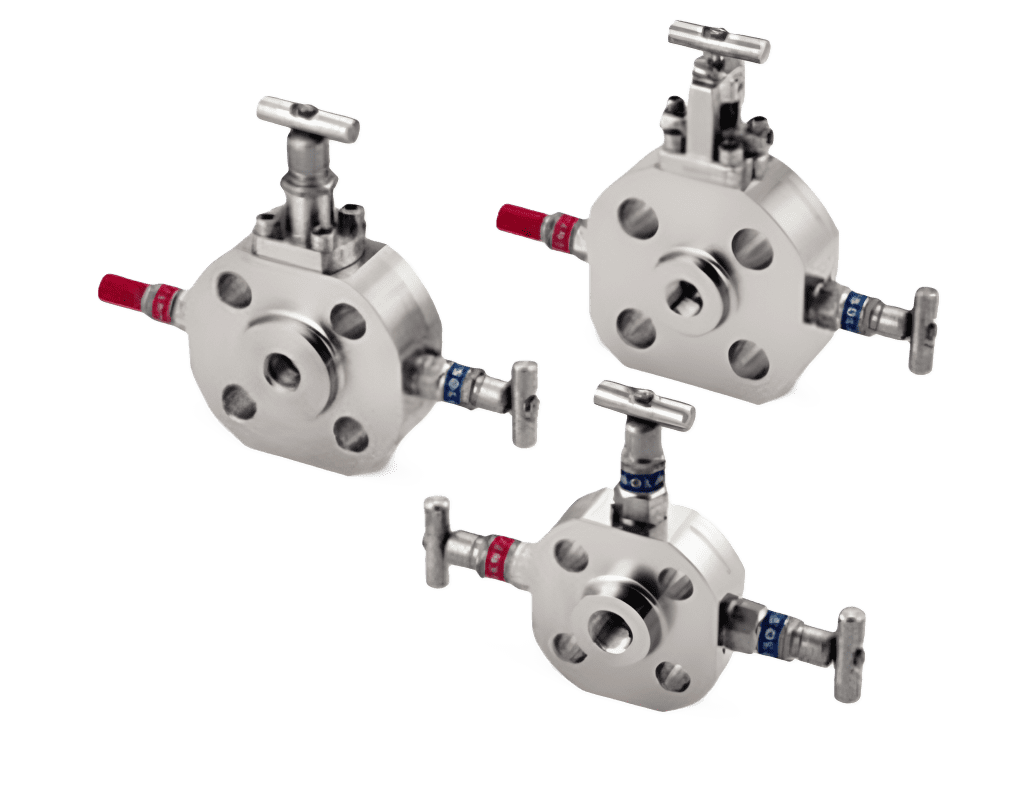

- Monoflange Valves

By combining customer-specified valves into a single manifold valve, BEPL’s Mono-Flange significantly reduces the number of potential leak paths. The Mono-Flanges also have a lower system mass, which reduces loading and vibration stresses, further improving safety and reliability. The BEPL Mono-Flange has needle valve primary and secondary rather than ball valves. The Mono-Flange is preferred by some operators as it is smaller than a traditional double block and bleed valve, giving even more space and weight advantages. This ensures that the Mono-Flange is it is a cost efficient option for owner / operators.

The Mono-Flange allows the mounting options to suit whether the pipeline is vertical or horizontal; the gauge or pressure transmitter can be fitted on either the front face or on the outer diameter of the body to allow good orientation and ease of reading.

BEPL’s Mono-Flange is available in a wide range of single-, two- and three-valve configurations, including block, double-block, block-and-bleed, double-block-and-bleed and block-bleed-block. Standard flange sizes include 1/2″, 3/4″, 1”, 1-1/2” and 2”, together with API and DIN standard versions, and there is an extensive choice of flange classes, from AN S I 1 5 0 to 2 5 0 0 . Standard outlet vents are 1/2″ female NPT.

Depending on Mono-Flange size and configuration, other options include 1/4″, 3/8”, 6 mm, 10 mm and 12 mm sizes, and male NPT or BEPL double ferrule compression fittings.

Features & Benefits of Monoflange Valves

- ]Heat code traceable and NACE compliant materials

- ]ISO 15848 Class A (HS) and B standards

- ]Integral two and single ferrule connections, which reduces potential leak paths

- ]Reduced installation costs - can be fitted faster than traditional valves

- ]Fire-safe versions that extend this to 538˚C (1000˚F)

- ]Corrosion resistant alloys

- ]Overall length reduced by ± 70% & weight reduced by ± 80%

- ]Brings pressure point closer to pressure measurement / instrument

- Reduced labour cost, reduced leak points & reduced need for support brackets

- Reduced bending moment/stress on primary piping connection

- ANSI B16.5 Flanged Inlet Connections 1/2″ to 2″ Sizes.

- Class 150 rated to Class 2500 rated

- Available in API Flanged Inlet Connections

- 1/2″ – 14 NPT (Female) Standard Outlet, 1/4″ x 18 NPT (Female) Standard Vent

- Standard Materials of Construction; A479 Type 316L and NACE, A105 Carbon

- Steel HASTELLOY® C276, MONEL®, INCOLOY® alloy 825, INCONEL® alloy 625, Duplex A182, Titanium

- Fire Safe designed to meet BS 6755 Part 2/API 607 are available on request