Atomic Energy

- Atomic Energy

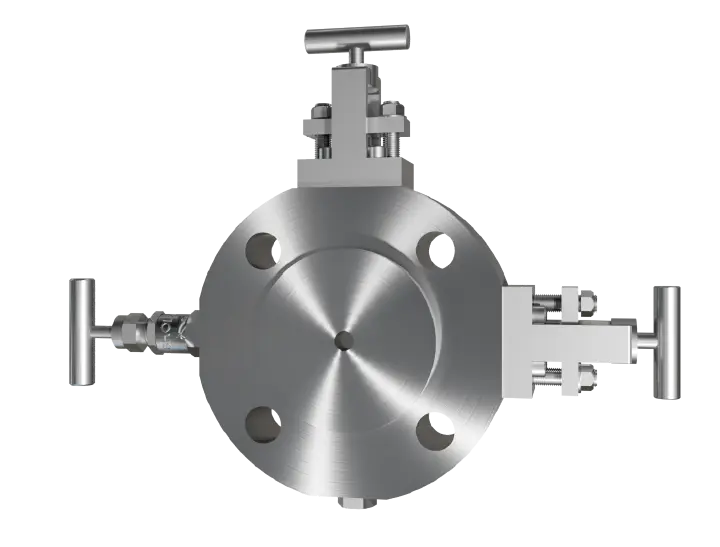

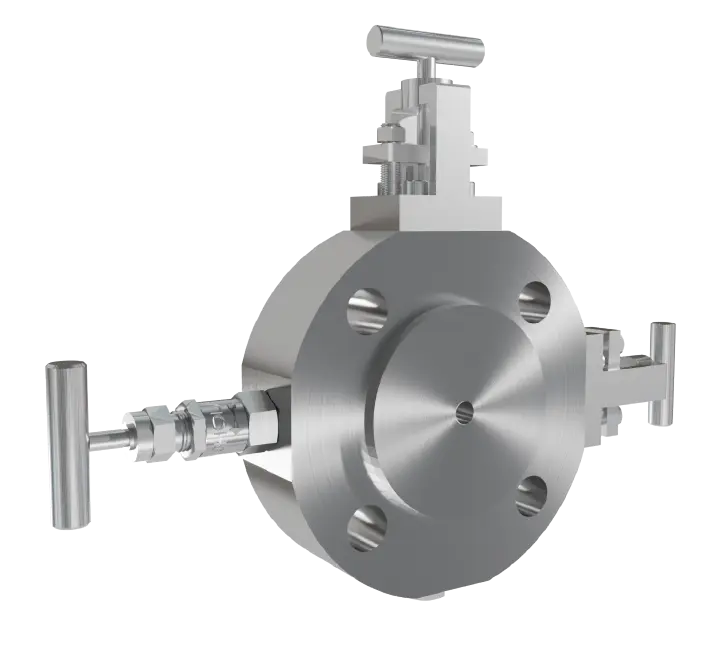

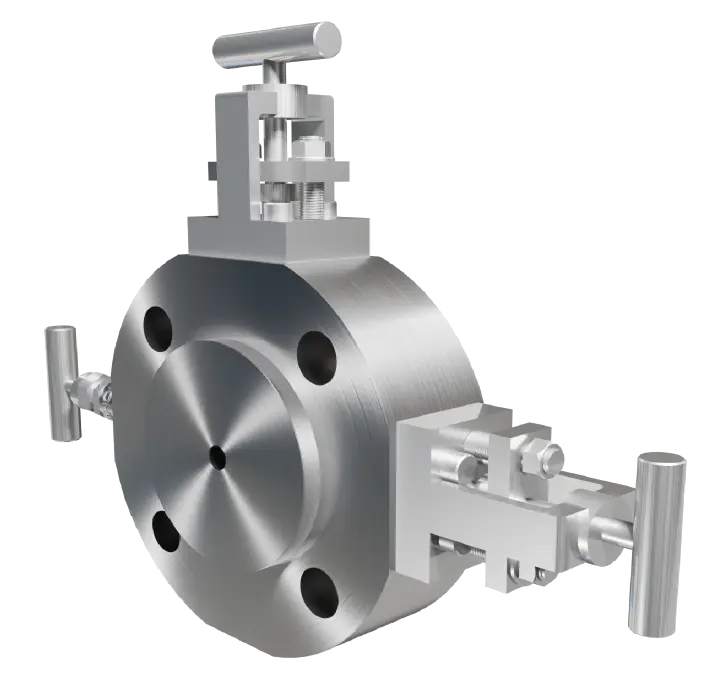

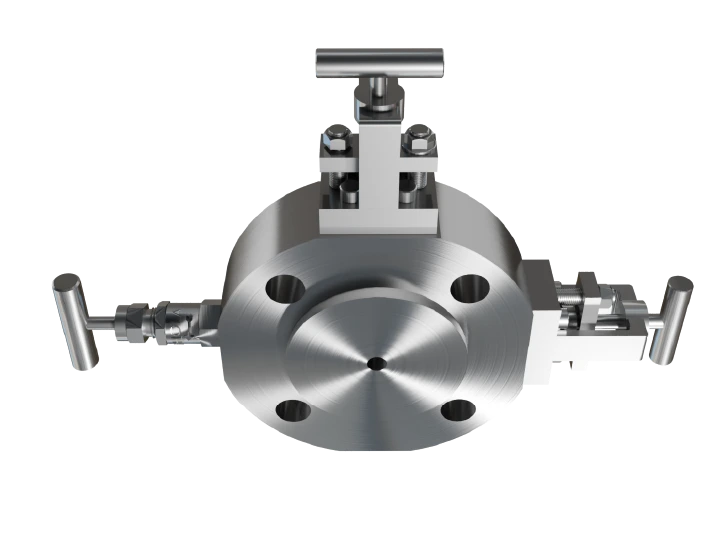

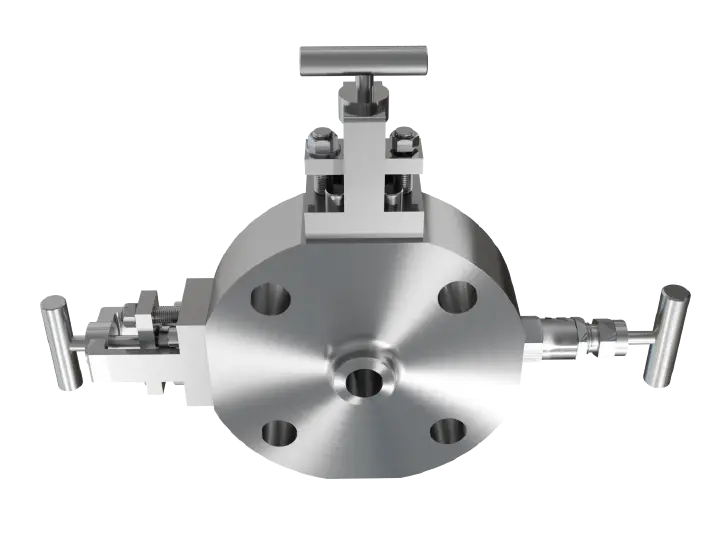

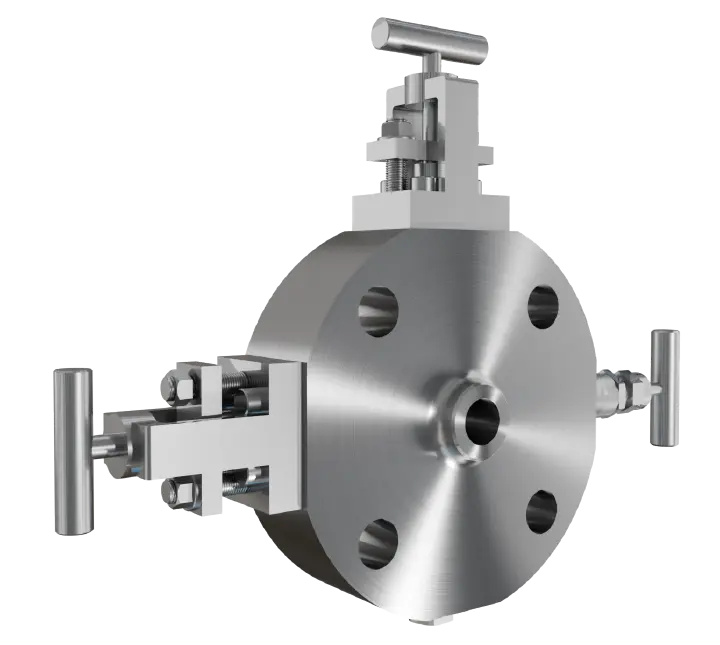

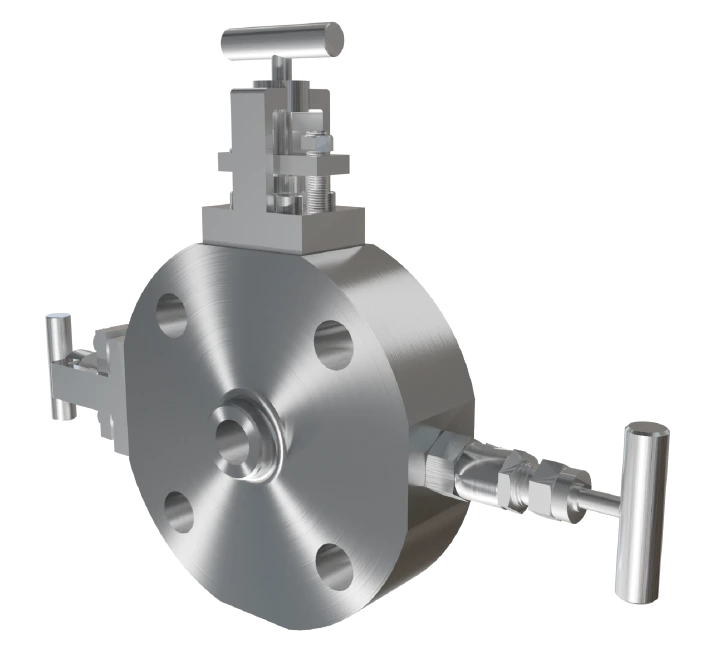

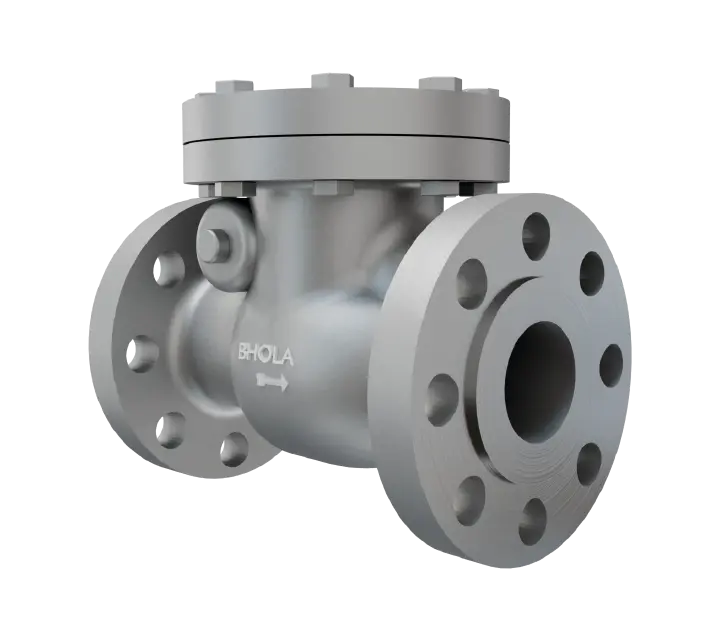

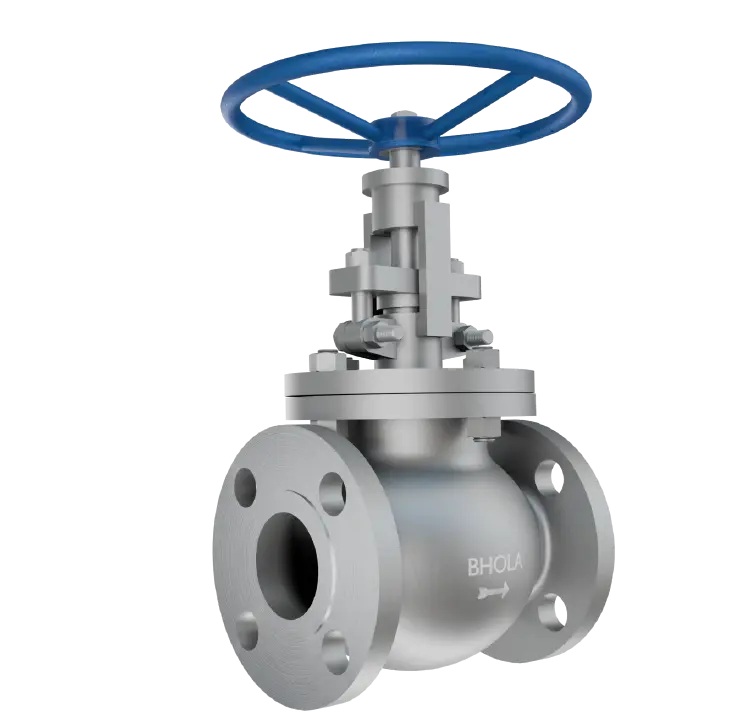

Valves play a crucial role in the operation of nuclear power plants, serving as the gatekeepers that control the flow of fluids and gases, regulate pressure, and maintain the smooth operation of the entire system. They are akin to the traffic controllers of the plant, ensuring that everything is moving in the right direction and at the right pace.

In essence, valves are essential for maintaining optimal conditions within the plant by regulating the flow of coolant, steam, and other fluids. Any malfunction or failure of valves can lead to significant issues such as disruptions in cooling systems and unexpected pressure spikes, posing a threat to the safety and efficiency of the plant.

At Bhola Engineers, we understand the critical importance of valves in the nuclear industry. That is why we meticulously consider all these factors when designing and manufacturing valves for atomic energy applications. Our dedicated team works tirelessly to ensure that our valves are not only reliable but also safe for use in nuclear power plants, meeting the stringent requirements and standards of the industry.