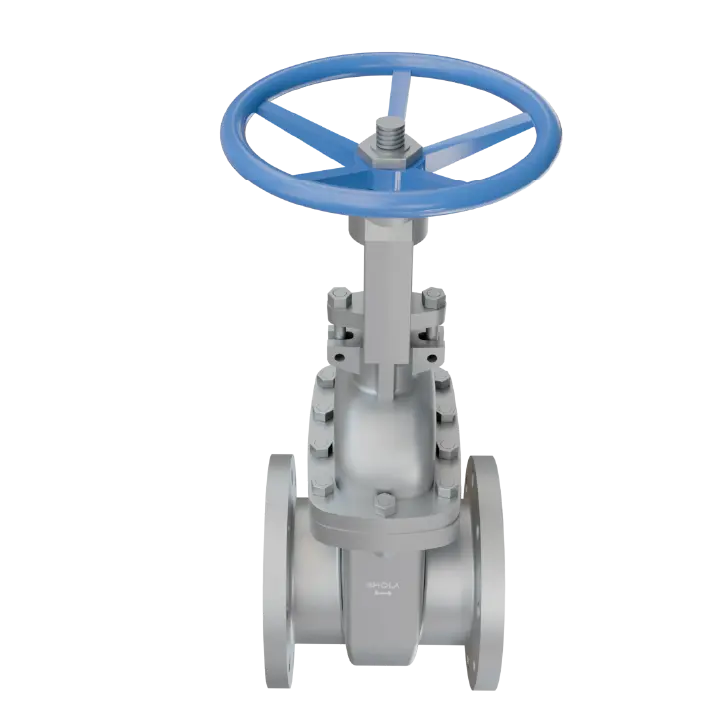

Gate Valves

- Gate Valves

The gate valve body has a straight through port without recesses except at the seat area. This ensures minimum turbulence, erosion and resistance to flow. Long integral guide ribs in the body match with guide slots in the wedge for accurate alignment and guidance. Bonnet castings are of one-piece design, where the yoke is integral with the bonnet for gate valves of sizes up to 12” (300mm). This ensures accurate alignment of stem and a smooth operation

Features & Benefits of Gate Valves

- ]Gate Valves are of flexible wedge; outside screwed and yoke type, bolted-bonnet construction.

- ]The gate valve body has a straight through port without recesses except at the seat area. This ensures minimum turbulence, erosion and resistance to flow.

- ]Long integral guide ribs in the body match with guide slots in the wedge for accurate alignment and guidance. Bonnet castings are of one-piece design, where the yoke is integral with the bonnet for gate valves of sizes up to 12” (300mm). This ensures accurate alignment of stem and a smooth operation.

- ]The body-bonnet joint for Class 150 gate valves is oval in shape, while for Class 300, this joint is circular in shape.

- ]Gate valves of Class 150 rating have a flat-face joint with a graphite gasket having metallic inserts.

- Valves of Class 300 rating have a male-female type joint with a spirally-wound gasket.

- Gate valves of Class 600 rating and above have a ring Type Joint (RTJ).

- A precision machined back-seat bush is threaded in the bonnet and is secured by a tab-weld.

- Gate valves feature a one-piece cast flexible wedge that minimizes stress concentration.

- Wedge flexibility ensures tight seating over a wide range of differential pressures and temperatures.

- It also adjusts to slight misalignments caused by pipeline deflections and thermal deformation. The stem-to-wedge thrust is applied close to the wedge centre. This reduces lateral stem loading and provides for more accurate wedge movement.

- The one-piece construction is securely fastened to the hinge by means of a lock nut and pin. The disc is free to rotate to avoid localized wear. The hinge pin offers Excellent wear resistance properties.

- Superior seal-welded seat ring that offers a leak proof design

- In 50mm gate valves, the seat ring is flared into the body

- Gate valve feature a stem of one-piece construction, ACME threaded and precision-machined with polished surfaces to reduce friction, minimise leakage and extend stem life.

- In gate valves, the heavy forged T-head engages with the T-slot in the wedge. The stem also has an integral self-adjusting radial back-seat shoulder that matches with the back-seat bush in the bonnet.

- Cast in austenitic, copper-free ductile iron alloy to provide resistance to heat, corrosion and wear, the Yoke Sleeve in gate valves features a long thread engagement that assures accurate alignment of the stem.

- Moreover, it can be removed without replacing the bonnet. In gate valves of sizes 150mm and higher in Class 600 rating and above, the yoke sleeve is mounted on thrust bearings to facilitate easy operation.

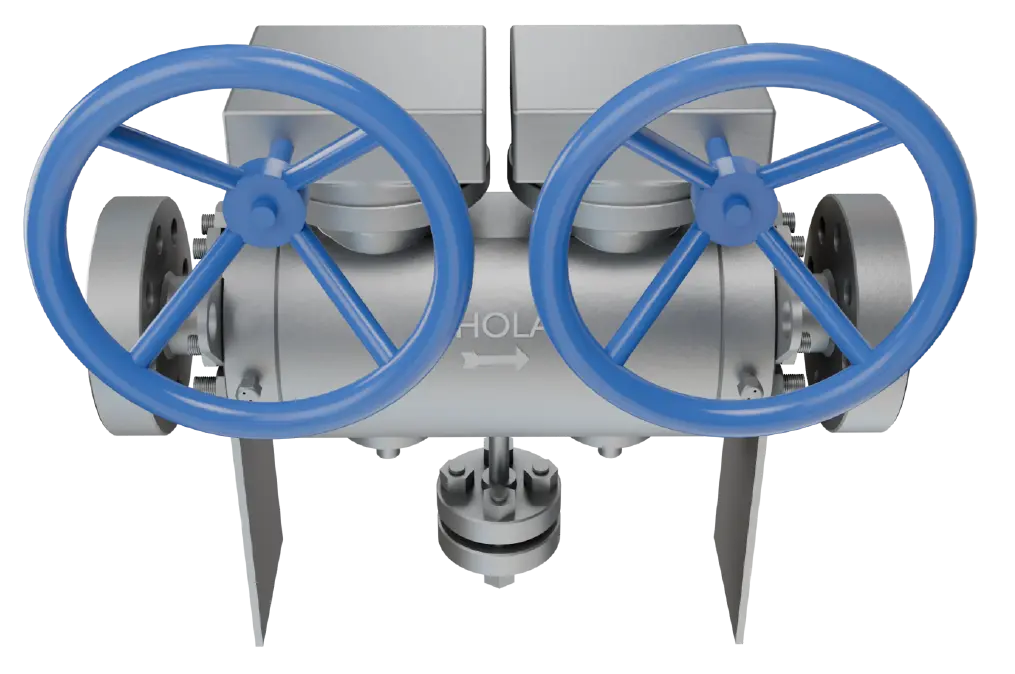

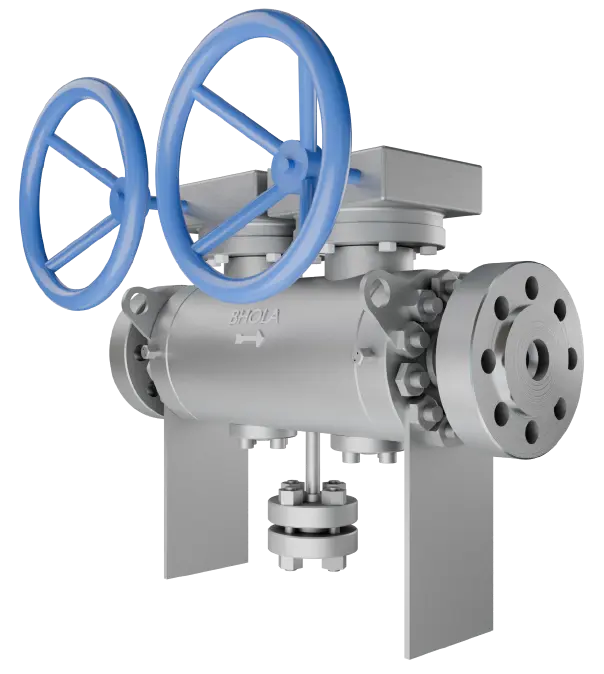

Types Of Gate Valves

- ]SOLID TAPER WEDGE GATE VALVE

- ]FLEXIBLE WEDGE GATE VALVE

- ]SPLIT WEDGE OR PARALLEL DISKS GATE VALVE

- ]SCREWED BONNET GATE VALVE

- ]BOLTED BONNET GATE VALVE

- ]WELDED BONNET GATE VALVE

- ]PRESSURE-SEAL BONNET GATE VALVE

- ]RISING STEM OR OS TYPE GATE VALVE

- ]NON-RISING STEM TYPE GATE VALVE